Laser Hardfacing Archives - Powder Keg

Welcome to the Laser Hardfacing Archives page of Powder Keg, a trusted and reputable provider of top-notch laser hardfacing services. We specialize in offering cutting-edge laser hardfacing solutions that significantly enhance the durability and performance of tools and equipment across various industries within the Business and Consumer Services sector.

What is Laser Hardfacing?

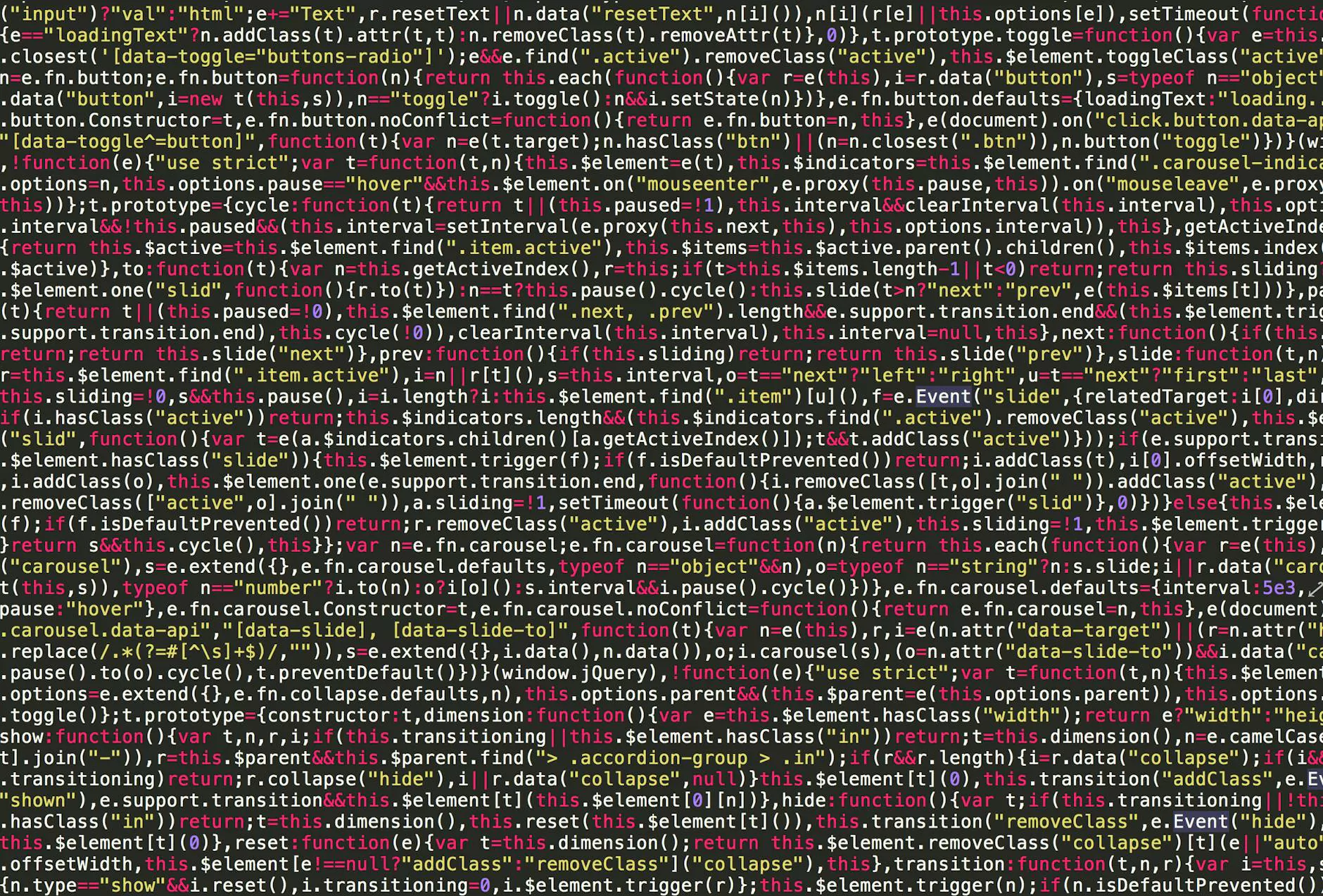

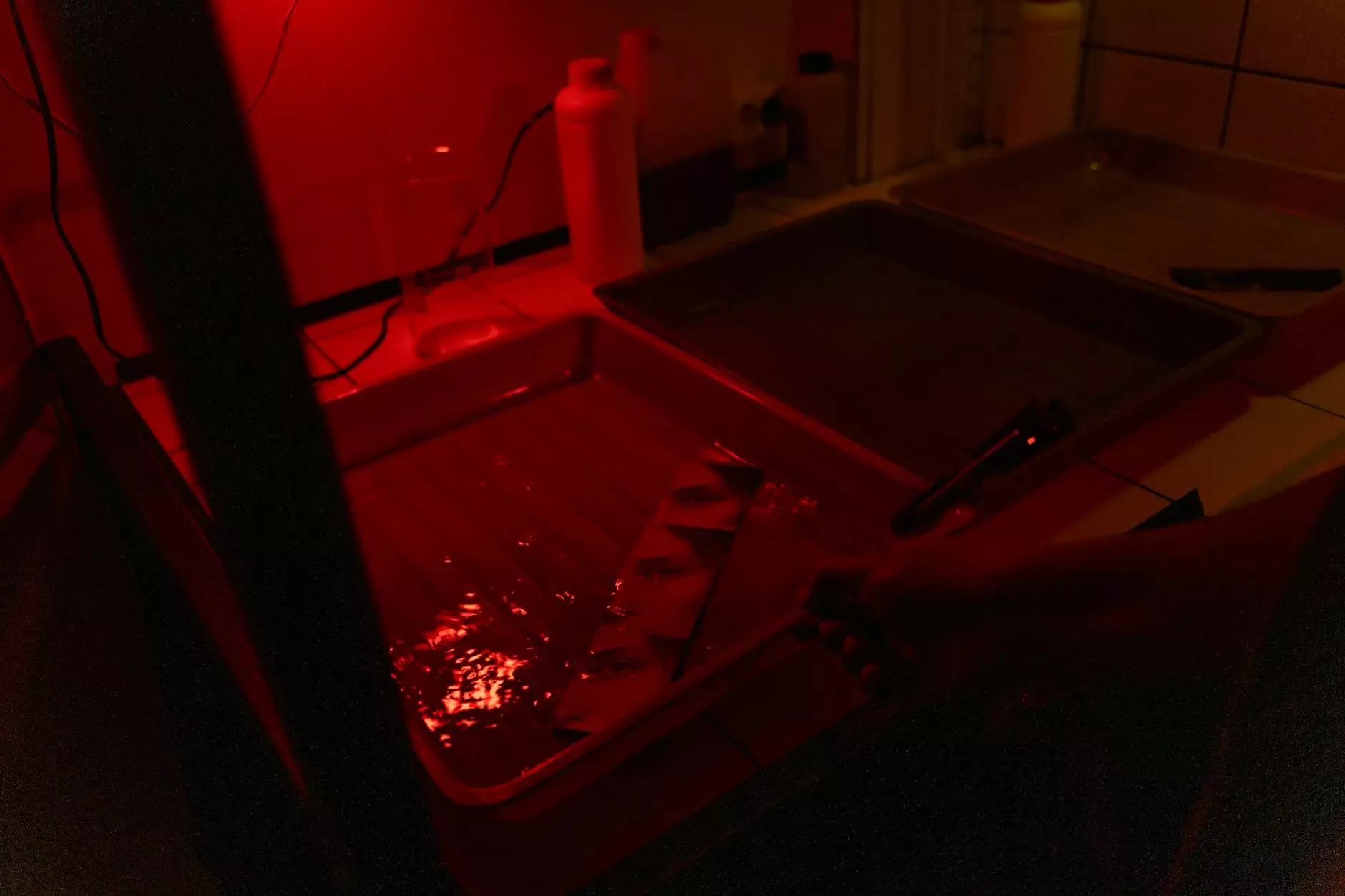

Laser hardfacing is a highly advanced and precise process that involves the deposition of a wear-resistant, high-quality metal alloy onto a surface. With our state-of-the-art laser technology, we are able to create a metallurgical bond between the base material and the hardfacing alloy, resulting in superior performance characteristics.

The Benefits of Laser Hardfacing

By choosing Powder Keg for your laser hardfacing needs, you can experience a wide range of benefits that will positively impact your business. Here are some key advantages:

- Enhanced Durability: Our laser hardfacing solutions significantly increase the wear resistance of your tools and equipment, prolonging their lifespan and reducing the need for frequent replacements.

- Improved Performance: With laser hardfacing, you can achieve superior performance characteristics, such as increased hardness, improved corrosion resistance, and reduced friction, leading to enhanced productivity and efficiency.

- Cost Savings: By extending the life of your tools and equipment, laser hardfacing helps you save money on replacements, maintenance, and downtime associated with frequent repairs.

- Versatility: Our laser hardfacing process can be applied to a wide range of materials, including steels, alloys, and even non-metallic substrates, allowing us to cater to diverse industry needs.

- Customization: We understand that every application is unique. That's why we offer tailored laser hardfacing solutions to meet your specific requirements, ensuring optimal results for your tools and equipment.

Applications of Laser Hardfacing

At Powder Keg, we have successfully implemented laser hardfacing solutions for various applications across numerous industries. Here are some common areas where our expertise can benefit your business:

- Manufacturing Industry: Laser hardfacing is widely utilized in the manufacturing sector to increase the lifespan and performance of components such as molds, dies, and cutting tools.

- Oil and Gas Industry: Our laser hardfacing services help improve the durability and resistance of critical equipment used in drilling, extraction, and refining processes.

- Heavy Machinery: By applying laser hardfacing to construction equipment, agricultural machinery, and mining tools, we enhance their reliability and resistance to wear and tear.

- Automotive Industry: Laser hardfacing ensures the longevity and performance of engine components, transmission parts, and other critical elements in vehicles, ensuring optimal functionality and safety.

- Aerospace Engineering: Our laser hardfacing expertise enables us to enhance the performance of aircraft engine components, turbine blades, and other critical parts used in the aerospace industry.

Why Choose Powder Keg for Laser Hardfacing?

When it comes to laser hardfacing services, Powder Keg stands out among the competition. Here's what sets us apart:

- Experience and Expertise: With years of experience in the industry, our team of skilled professionals possesses in-depth knowledge and expertise in laser hardfacing, ensuring exceptional results every time.

- State-of-the-Art Technology: We invest in cutting-edge laser equipment and technology, allowing us to provide precise, efficient, and high-quality laser hardfacing services that meet the highest industry standards.

- Custom Solutions: We understand that each project is unique. That's why we offer customized laser hardfacing solutions tailored to your specific requirements, ensuring optimal results for your tools and equipment.

- Commitment to Quality: At Powder Keg, we take pride in delivering nothing but the best. We prioritize quality control at every stage of the laser hardfacing process, ensuring that you receive exceptional, long-lasting results.

- Client Satisfaction: Our commitment to customer satisfaction is paramount. We strive to exceed your expectations by providing personalized attention, timely delivery, and excellent customer service throughout your laser hardfacing journey with us.

Experience the incredible benefits of laser hardfacing for your tools and equipment. Choose Powder Keg for top-of-the-line laser hardfacing services backed by expertise, cutting-edge technology, and unwavering commitment to quality.